Product Details

Fire Suppression Systems

Products

Blowers & Fans

Valves & Nozzles

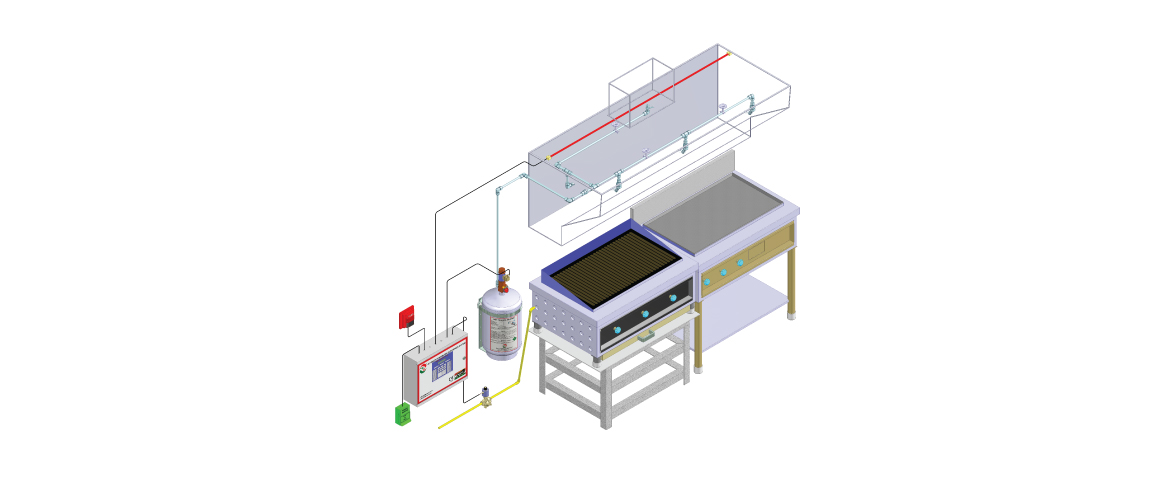

Automatic Kitchen Fire Suppression System

Tech US Automatic Kitchen Fire Suppression System features a proprietary mechanical base that uses fusible link technology to detect and actuate the release of the extinguishing agent. This fully automatic, mechanically activated system is more flexible, space-efficient, and cost-effective than traditional systems. Designed to NFPA and UL standards, it provides reliable protection for kitchen hoods, effectively addressing high-temperature oil fires in commercial kitchens such as hotels, institutes, and restaurants.

A. System Design & Operation

-

Components:

Wet agent tank, heat sensing cable, nozzles, and piping.

-

Optional:

Temperature sensor.

-

Actuation:

Automatic and manual options.

-

Activation:

Sprays special form type fire suppressant on the plenum area, cooking surface, and exhaust duct at a predetermined flow rate.

-

Suppression Mechanism:

Forms a soap-like foam layer on hot grease, insulating it from the atmosphere and cutting off oxygen supply.

-

System Capabilities:

Can shut down other appliances upon actuation, if required.

-

Integration:

Additional equipment such as gas shutoff valves, alarms, and warning lights can be integrated into the system.

B. System Operation Explanation

In the event of a fire, the detection module within the Tech US System triggers system activation upon detecting temperatures exceeding a predefined threshold. This fire detection mechanism offers flexibility, employing either electrical triggering or mechanical fusible links to ensure prompt and reliable response to fire incidents.

C. Equipment Applicable

The Tech US Automatic Kitchen Fire Suppression System undergoes extensive performance and safety testing on a broad spectrum of cooking equipment and appliances, including deep fat fryers, griddles, skillets, woks, salamanders, chain broilers, split chain broilers, split deep fat fryers, and range tops with circular pots.

The testing process includes a variety of cooking fuels, such as vegetable oil, semi-solid grease, shortening, mesquite wood, lava pumice, and charcoal, as well as different types of low-fat meats. These rigorous evaluations ensure comprehensive coverage and reliable protection across numerous fire scenarios.

D. System Configuration

| Cylinder Size | Nozzles |

|---|---|

| 9 Ltrs | 3 |

| 12 Ltrs | 4 |

| 15 Ltrs | 5-7 |

| 21 Ltrs | 8-10 |

| 24 Ltrs | 11-13 |

| 27 Ltrs | 14-16 |

| 30 Ltrs | 17-20 |

E. Key Features

-

Fully Mechanical System:

No need of out source of power.

-

Protection:

Provides constant, 24X7 protection, ensuring continuous and reliable safety.

-

Overlapping:

Design enables reordering of cooking ranges for operational flexibility.

-

Manual Pull Station:

The manual release permits system activation upon initial fire detection preempting automatic deployment.

-

Various Nozzle Designs:

Three nozzle types ensure universal system compatibility and functionality. Metal caps prevent grease buildup and obstructions.

-

Integrated Gas Shut-Off Valve:

The integrated gas shut-off valve automatically ceases gas supply, thereby enhancing safety and security of the premises.

-

SS Agent Cylinder:

Stainless steel cylinder and bracket components ensure long-term, corrosion-free and reliable operation.

-

Quick Installation:

Efficient deployment of kitchen fire suppression system with streamlined installation process, ensuring rapid implementation and reliability.